Find the perfect product for your needs using our advanced search bar. Filter by appearance, color, intended use, and format, or search directly for a series by name and discover a wide range of solutions for your project.

Discover the Perfect Solution for Your Project

Find the perfect product for your needs using our advanced search bar. Filter by appearance, color, intended use, and format, or search directly for a series by name and discover a wide range of solutions for your project.

Discover how our products

transform your environment

try now

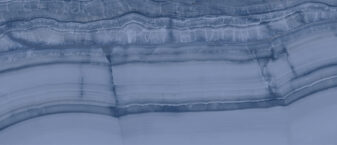

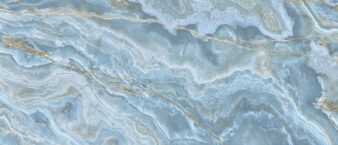

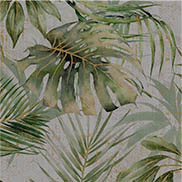

Welcome to the world of high-end Italian ceramics!

We are LA FABBRICA AVA, a leading brand in the field of flooring and wall coverings, dedicated to transform your spaces into authentic works of art. We stand out for “high product quality,” “innovative design,” and “creativity.” Our passion for excellence guides us through every phase, from designing to interior design, and it is reflected in the cutting-edge collections we create. Our solutions are supported by the most advanced technologies, allowing us to meet the complex technical needs of architecture and interior design. The result? A unique and elegant style, typically “Made in Italy.”

Projects

Welcome to the Project Gallery of La Fabbrica AVA: the place dedicated to architects, designers and interior design enthusiasts, but also to those who have been able to enhance their spaces thanks to our products.